In today’s era of industrial automation, Programmable Logic Controllers (PLCs) play a pivotal role in controlling machinery and processes. These devices are crucial components in various industries, enabling efficient and precise control over manufacturing processes. As the demand for automation continues to rise, the market for PLCs is witnessing significant growth, with several key players dominating the manufacturing sector.

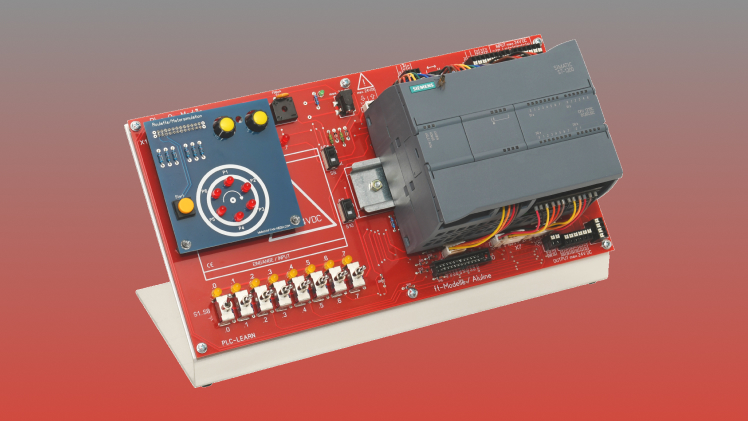

Siemens AG

Siemens AG is a renowned multinational conglomerate headquartered in Germany. With a rich history dating back to the 19th century, Siemens has established itself as a global leader in industrial automation and electrification solutions. The company’s extensive product range includes PLCs tailored for diverse applications, ranging from small-scale machinery to complex industrial systems. Siemens PLCs are known for their reliability, performance, and advanced features, making them a preferred choice for industrial automation projects worldwide.

Rockwell Automation

Rockwell Automation, based in the United States, is another prominent player in the PLC manufacturing industry. The company offers a comprehensive portfolio of automation solutions, including PLCs, HMI (Human-Machine Interface) devices, and software platforms. Rockwell Automation’s PLCs are renowned for their scalability, flexibility, and seamless integration with other automation components. With a strong global presence and a focus on innovation, Rockwell Automation continues to drive advancements in industrial automation technology.

Schneider Electric SE

Schneider Electric SE, a French multinational corporation, is a leading provider of energy management and automation solutions. The company’s PLC offerings cater to a wide range of industries, including manufacturing, energy, and infrastructure. Schneider Electric PLCs are known for their efficiency, durability, and eco-friendly design. Leveraging cutting-edge technologies such as IoT (Internet of Things) and cloud connectivity, Schneider Electric remains at the forefront of industrial automation innovation.

Mitsubishi Electric Corporation

Mitsubishi Electric Corporation, based in Japan, is renowned for its diverse portfolio of electrical and electronic products. The company’s PLCs are widely used in industrial automation applications, thanks to their high performance, reliability, and versatility. Mitsubishi Electric PLCs are known for their robust construction, advanced programming capabilities, and seamless integration with peripheral devices. With a strong focus on R&D, Mitsubishi Electric continues to introduce innovative PLC solutions to meet evolving industry needs.

ABB Group

ABB Group, headquartered in Switzerland, is a global leader in electrical and automation technologies. The company’s PLC offerings include a wide range of products that are used for various industries including robotics, manufacturing, etc..

The best way to buy PLC

The first step to buying a PLC is to determine your needs. The environment where the device is to be installed, the accuracy range of the device, the ambient temperature, etc. must be carefully checked. The next step is to choose a reliable online store to buy industrial equipment like PLCKing .

FAQs

Are PLCs only used in manufacturing industries?

While PLCs are commonly associated with manufacturing, they are also utilized in various other sectors such as energy, utilities, and transportation for automation purposes.

What are some advantages of using PLCs in industrial automation?

PLCs offer advantages such as flexibility, reliability, real-time monitoring, and easy troubleshooting, which contribute to improved efficiency and productivity in industrial processes.

How do PLCs differ from traditional relay-based control systems?

PLCs provide greater flexibility, scalability, and programming capabilities compared to traditional relay-based systems, allowing for more complex automation tasks and easier maintenance.

What role do PLC manufacturers play in supporting sustainability initiatives?

PLC manufacturers are increasingly focusing on developing energy-efficient and eco-friendly solutions to support sustainability initiatives and reduce the environmental impact of industrial operations.

What are some key considerations when selecting a PLC for industrial automation projects?

Factors such as performance, scalability, compatibility with existing systems, support services, and long-term reliability should be carefully evaluated when choosing a PLC for industrial automation applications.

Is it necessary to buy PLC?

It depends on your specific needs and the nature of your project. PLCs (Programmable Logic Controllers) are used to control machinery and automate processes in industrial and manufacturing settings. If you are working on a project that involves automation, precise control of machinery, or monitoring of industrial processes, a PLC may be necessary. However, for simpler or small-scale projects, there may be alternative solutions that could suffice. It’s best to assess your requirements and do some research to determine if a PLC is the right choice for your needs.